Dongguan Haochen Mould Factory

Contact: Mr. Li

Mobile phone: 0086+13922512135

Q Q: 89180037

Q Q: 2649528748

Phone: 0086769-83511708

Phone: 0086769-83511798

Fax: 0086769-83511508

Email: liwei@haochenmj.com

Website: www.haochenmj.com/en

Address: No. 58, Lishi Industrial Zone, Huangjiang Town, Dongguan City

With the needs of production, few branches of metal processing can be as dynamic as mold manufacturing. Therefore, constantly seeking the latest skills and innovative ideas is essential for any mold factory to be in a leading position. Here are some skills development that will help invent opportunities or provide a leading position for mold processing.

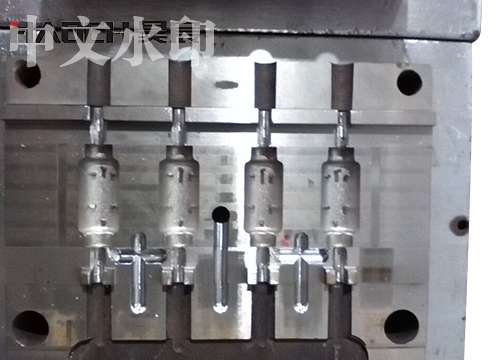

First and foremost parallel processing, the core and cavity of the data line plug mold are combined into one part and processed in parallel on a multi-task machine. Using the flexible tilting milling spindle (b-axis) and reverse turning spindle (c-axis), the cooling holes on the four surrounding surfaces and the back of the rectangular workpiece are finished by milling. The core and cavity parts are processed while the workpiece is still merged into one. Through the harmony of the turning of the turning spindle and the tilting of the milling spindle, optimizing the orientation of the tool can improve the surface roughness and advance the tool life. The workpiece can also be rotated periodically to facilitate dumping of chips. The core and cavity are then separated, each of which is still firmly clamped on the reverse turning spindle. Plane milling was performed on two of the two exposed peripheral surfaces, and the cooling holes on the two of the mold were all drilled in one clamping. Compared with traditional processing, this method greatly reduces the number of clampings and procedures. Since the two of the molds adhere to each other with excellent orientation until they are separated, the accuracy also advances.

The second point, the five-axis gun drilling process, the ability to drill water pipes with compound angles makes it possible to advance the cooling function of large molds. The five-axis gun drill processing machine becomes possible by eliminating multiple clutters and achieving excellent economy. The molds used for car bumpers, car dashboards and other plastic parts rely on rapid and useful cooling to obtain a competitive production cycle. None of these solutions are very attractive, and they are not even satisfying the customer's desire to lower the mold quotation.

Data line plug mold manufacturing and processing skills: This machine is characterized by a programmable rotary table and a cnc spindle head that is 25 degrees more than the lower limit of the normal rotation plan and 15 degrees more than the upper limit. The machine can be equipped with traditional gun drills, sts (single tube system) type drills, or both. When using the latter drill with a diameter of 1 inch in deep hole drilling, the speed is as high as 9 inches per minute. The skill control system of the machine tool can flash the oil pressure, flow, feed resistance and torque graphically in real time. This means that the optimal drilling speed can be monitored while drilling, reducing the risk of tool damage. The machine tool has good planning rigidity and can also perform high-speed milling, drilling and tapping. It needs to be equipped with an optional tool changer.

Benefits of injection molding and blow molding:

(1) When the melt is written into the cavity of the parison mold, a certain orientation effect is encountered in the circumferential direction. In addition, the temperature of the parison during inflation is lower than that of extrusion blow molding, and the orientation effect of the blowout can be retained more, which helps the strength of the forward container and other functions.

(2) The container specification (especially the neck thread specification) has high accuracy: it is easier to ensure the uniformity of the container wall thickness as requested, and the container specification is uniform.

(3) There is no joint seam on the container and no trimming is needed, usually no scraps (extrusion blow molding scraps are usually 5%-30%).

(4) A sliding bottom module can be set on the blow mold, so the shape of the container bottom has greater flexibility in planning.

(5) It is more suitable for molding rigid plastic containers and wide-mouth containers.

(6) The container has high gloss, and the container made of transparent polymer is always transparent.

Phone: 0086769-83511708 / 0086-13922512135

Phone: 0086769-83511708 / 0086-13922512135

Email: liwei@haochenmj.com

Email: liwei@haochenmj.com

Address: No. 58, Lishi Industrial Zone, Huangjiang

Address: No. 58, Lishi Industrial Zone, Huangjiang

Town, Dongguan City

扫一扫,查看手机