Dongguan Haochen Mould Factory

Contact: Mr. Li

Mobile phone: 0086+13922512135

Q Q: 89180037

Q Q: 2649528748

Phone: 0086769-83511708

Phone: 0086769-83511798

Fax: 0086769-83511508

Email: liwei@haochenmj.com

Website: www.haochenmj.com/en

Address: No. 58, Lishi Industrial Zone, Huangjiang Town, Dongguan City

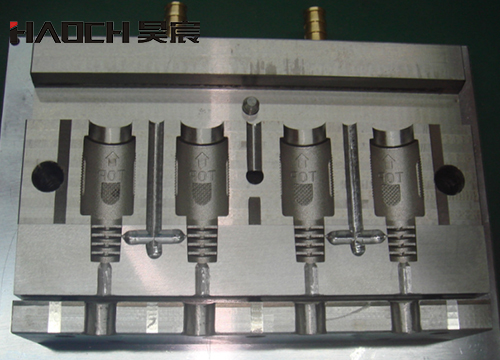

Influencing factors of DC plug mold life

1. Influence of DC plug mold structure

The structure of the DC plug mold has a great influence on the stress state of the DC plug mold. The reasonable DC plug mold structure can make the DC plug mold work evenly under stress, not easy to be biased, and the stress concentration is small. There are many types of DC plug molds, the forms are very different, and the working environment is also different. The following discusses from several aspects with common characteristics.

(1) Corner radius The corner radius is divided into an outer (convex) corner radius and an inner (concave) corner radius. The size of the radius of the working part not only affects the forming process and the quality of the formed parts, but also affects the failure form and life of the DC plug mold.

(2) DC plug mold structure

①The integral DC plug mold and the inlaid DC plug mold The concave fillet radius of the overall DC plug mold is likely to cause stress concentration and thus cracking.

② The DC plug mold is guided by the DC plug mold of the guide device, which can ensure the accuracy of the relative positions of the relevant parts in the DC plug mold, increase the DC plug mold's ability to resist bending and eccentric load, and avoid uneven wear of the DC plug mold.

2. The influence of working condition of DC plug mold

(1) Material and temperature of molded parts

①Materials The materials of molded parts are metal and non-metal. Generally speaking, the strength of non-metallic materials is low, the required forming force is small, the DC plug mold stress is small, and the DC plug mold life is long. Therefore, the metal forming die has a lower life than the non-metal forming die.

② Temperature When forming a high-temperature workpiece, the DC plug mold heats up due to receiving heat. As the temperature rises, the strength of the DC plug mold decreases and plastic deformation is likely to occur. At the same time, the temperature of the surface of the DC plug mold in contact with the workpiece and the non-contact surface are very different, causing temperature stress in the DC plug mold.

(2) Equipment characteristics

① The accuracy and rigidity of the equipment The power of the DC plug mold forming workpiece is provided by the equipment. During the forming process, the equipment will be elastically deformed due to the force.

②The force of the speed equipment on the DC plug mold and the workpiece gradually increases over a period of time, and the speed of the equipment affects the force application process. The higher the speed of the equipment, the greater the impact force (large impulse) received by the DC plug mold per unit time; the shorter the time, the impact energy is too late to be transmitted and released, and it is easy to concentrate locally, causing local stress to exceed the yield stress of the DC plug mold material Or breaking strength. Therefore, the higher the equipment speed, the easier the DC plug mold is to break or fail to plastically deform.

(3) Lubrication

Lubricating the relative moving surface of the DC plug mold and the blank can reduce the direct contact between the DC plug mold and the blank, reduce wear, and reduce the forming force. At the same time, the lubricant can also hinder the heat transfer of the blank to the DC plug mold to a certain extent, and reduce the temperature of the DC plug mold, which is beneficial to improving the life of the DC plug mold.

3. The influence of DC plug mold material performance

The performance of the DC plug mold material has a great influence on the life of the DC plug mold. These properties include: strength, impact toughness, wear resistance, corrosion resistance, hardness, thermal stability and heat fatigue resistance.

4. The influence of DC plug mold manufacturing process

(1) When the module is forged, the temperature difference stress caused by the internal and external temperature difference caused by the module heating and cooling will cause cracks in the forging billet if the technical parameters such as upsetting, punching and expanding are improperly selected. In addition, when the forging ratio exceeds a certain value, due to the formation of fibrous structure, the transverse mechanical properties drop sharply, leading to anisotropy.

(2) In the electrical processing of DC plug molds, different levels of metamorphic layers will appear. In addition, due to local sudden heat and rapid cooling, residual stress and cracks are also likely to form.

(3) Heat treatment of DC plug mold

The heat treatment of the DC plug mold is arranged after module forging and rough machining, and is almost the final process of DC plug mold processing. The selection of the DC plug mold material and the determination of the heat treatment process have a great influence on the performance of the DC plug mold

Phone: 0086769-83511708 / 0086-13922512135

Phone: 0086769-83511708 / 0086-13922512135

Email: liwei@haochenmj.com

Email: liwei@haochenmj.com

Address: No. 58, Lishi Industrial Zone, Huangjiang

Address: No. 58, Lishi Industrial Zone, Huangjiang

Town, Dongguan City

扫一扫,查看手机